Platinum is a non-reactive metal that nature has small in amounts. Cobalt-60, a radioactive isotope, is used to cure cancer and irradiate food in certain nations to preserve it. People used Cobalt salts in paint, porcelain, glass, pottery, and enamels to create beautiful blue colours for millennia. Because of its appealing look, hardness, and corrosion resistance, it is sometimes prevalent in electroplating. High-temperature applications such as jet turbines and gas turbine generators are also one of the uses of cobalt. However, alloy with aluminium and Nickel produces powerful magnets. People usually extract cobalt via mining, and Congo and Zambia on the African continent are famous for Cobalt mining.Īpplication: Because cobalt, like iron, can be magnetic, the manufacture of magnets is an example of the use of cobalt. It is one of the d-block elements, or transition metals, on the periodic table.Ĭobalt, like many other transition metals, is usually found in the form of an alloy. It is an underappreciated metal with a wide range of applications, fascinating facts, and dynamic characteristics. On the other hand, the low metal-to-metal friction of the material makes it ideal for high-stress situations, such as those found in bushings and bearings. Because of its excellent corrosion resistance, shipyards often choose bronze fittings and propellers on many boats and ships.īecause of their high electrical conductivity, certain bronze alloys are incredibly suitable for electrical applications. Bronze has a reddish-brown hue, is complex and brittle, and has a melting temperature of 950 degrees Celsius.Īpplications: The properties of bronze make metal ideal for both practical and aesthetic uses, such as marine and fishing.

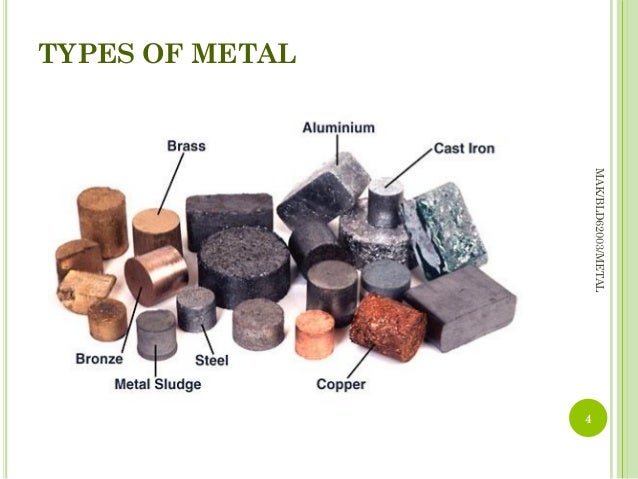

Leaded bronze, Phosphor bronze, Aluminum bronze, Silicon bronze, and Manganese bronze are some of the most common bronze alloys from these combinations.īronze has many distinct characteristics that make it ideal for various uses, from art to computer technology. Aluminium, arsenic, manganese, phosphorus, and silicon, for example, have distinct characteristics. Cast Ironīronze is a metal alloy mainly of copper and containing 12% tin. They have a mixture of cobalt, molybdenum, and tungsten elements and are the fundamental cause for tool steel’s superior heat resistance and endurance properties.Īpplication: Sheets for deep-drawn automobile bodies and appliances, all kinds of construction, railroad rails, and wires, etc. These metals get their name because they’re often used to manufacture metal tools, such as hammers. Tool steel: Tool steel is famous for its hardness and resistance to heat and abrasion.This combination makes the steel corrosion-resistant and extremely easy to mold into various forms. This kind is lustrous and has 10 to 20% chromium as its primary alloying ingredient. Stainless steel: Stainless steels are by far the most popular on the market.The concentration of the ingredients determines the strength of these alloys. Automobile components, pipelines, ship hulls, and mechanical projects prefer alloy steels since they are less expensive and more corrosion resistant. Alloy steels: Alloy steel combines multiple metals such as Nickel, copper, and aluminum.Low, medium, and high carbon steel are the three kinds, with low having approximately 0.30 percent carbon, medium 0.60 percent, and high 1.5 percent. Carbon Steels: Carbon steel has a dull, matte appearance and it is corrosive.It is an iron alloy with a few tenths of carbon added to enhance strength and fracture resistance compared to other iron types. Steel, cast iron, and wrought iron are the three most prevalent kinds of ferrous metals. Their characteristics make them ideal for skyscrapers, bridges, railroad projects, and vehicles in industrial and architectural sectors. The hardness, durability, and tensile strength of ferrous metal are prevalent in manufacturing. Three types of Ferrous MetalsĪny metal with high iron content and magnetic characteristics is ferrous metal. However, we’ve divided the lists into ferrous metals and non-ferrous metals to keep things easy. Today’s post will go through the top twenty metals that are the most popular in industrial manufacturing. The big companies are now using these metals in thousands of applications based on market demand. However, modern scientists further developed these metals and discovered new elements. In the later periods, they developed these different types of metals requiring for other applications. After the bronze age, people discovered several metals, which lasted from roughly 3300BC to 1200BC, and utilized them for various uses.

0 kommentar(er)

0 kommentar(er)